|

Size |

size |

| 1220*2440mm | 1280*2500mm |

| 1260*2460mm | 1550*3050mm |

| 2000*3000mm | 1230*1830mm |

| 2030*3030mm | 1000*2000mm |

| 1200*1800mm | 2050*2050mm |

| 1300*2000mm | 1200*2350mm |

| customized size is ok. |

|

Introduction:

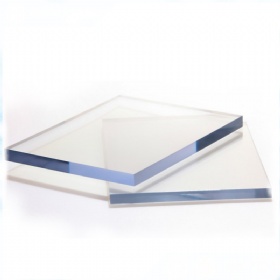

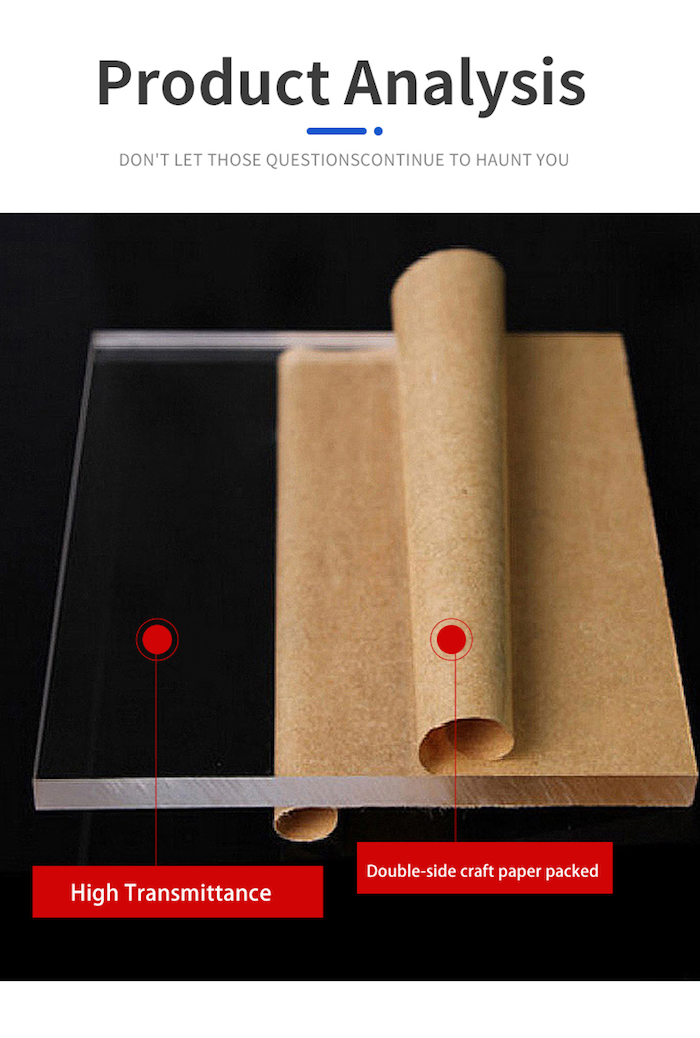

Acrylic has a high degree of transparency, light transmission rate of 92%,the "plastic crystal" reputation.And has excellent weather resistance, especially applied to outdoor, ranking the highest in other plastics, and both a good surface hardness and gloss, processing plasticity, can be made into a variety of shapes and products needed.Another wide variety of rich color plates (with a translucent color palette),another feature is able to maintain high transparency thick.

Features:

1,Good weather resistance and acid alkali resistance

2,Long service time

3,Good light transmission, light transmittance>92%,only need small light intensity, saving electric energy

4,Strong impact resistance, is sixteen times that of ordinary glass, suitable for installation in the special needs of the safety zone

5,Excellent insulation properties, suitable for all kinds of electrical equipment

6,Light weight, only half weight of ordinary glass

7,Bright color, high brightness

8,UV light resistance

9,High plasticity,Processing and shaping easier.

Applications:

1,Construction: show window, doors, light-absorpting shade, telephone booth.

2,Advertisement: lamp house, signboard, indicator, display rack.

3, vehicle: door and window of car and train.

4,Medical: infant incubator, many kinds of medical apparatus.

5,Civilian goods: bath room,art work,cosmetics,bracket.

6, Industrial: instruments and meters and protecting cover 7. Lighting: daylight lamp, ceiling lamp, lampshade

8,Advertisement exhibition & display, digital printing, silk screen printing, engraving materials,etc.

9,Fumiture office furniture, cabinet, bath cabinet, etc.

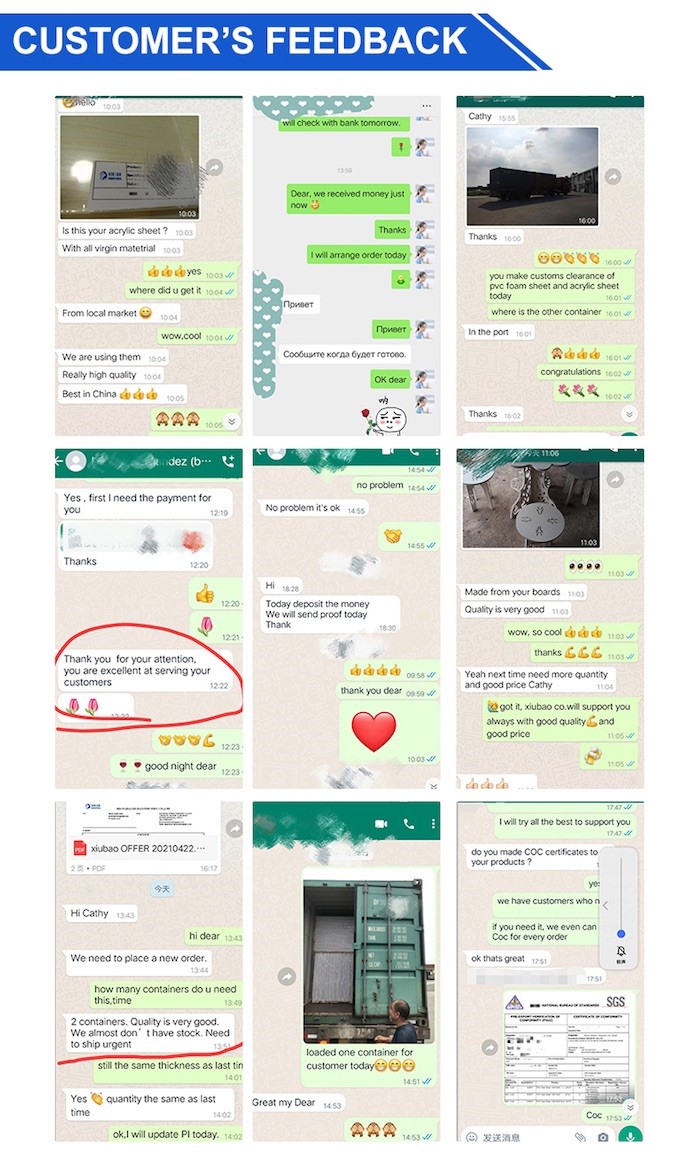

Inspect before shipment.

Shipment:

1. What is your popular color?

Color code :000, 425, 422, almost for every order, customers will buy these codes.

2. Is Plexiglass Cast Acrylic?

Generally speaking, when someone is referring to plexiglass they mean “clear acrylic.” Plexiglass comes in many forms such as a clear cast sheet or a clear extruded sheet. The terms are often used interchangeably. Plexiglas (written with one “s”), however, is a brand name of cell cast acrylic.

Cast acrylic can be created using two different techniques, batch cell and continuous production. Batch cell is a molding process often used to make tubes and rods. On the other hand, continuous production, which shares the name of casting, is a quick process that runs nonstop, requiring less labor.

Cast acrylic sheets are lightweight, available in a variety of colors and thicknesses, and features greater thermal stability than in extruded form. Of the two, cast acrylic sheets have greater optical clarity. It is slightly harder overall in this form versus extrusion. When engraved, cast acrylic sheets result in a frosted appearance, as opposed to clear engraving on extruded sheets. Common applications for cast acrylic sheets include Point-Of-Purchase (POP) and store displays, skylights, furniture, picture frames, products for the aerospace industry, and because of its greater resistance to temperature fluctuation, ice rinks.

For more info, pls come back to another FAQ.

Shanghai Xiubao Industry Co., Ltd

Shanghai Xiubao Industry Co., Ltd